January 2024

January 2024

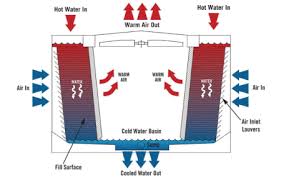

Cooling towers are vital components in many residential, industrial and commercial settings, responsible for dissipating excess heat from mechanical systems.

During winter, when cooling demands are low, cooling towers are typically shut down. This dormant period offers a perfect opportunity for maintenance and crucial repairs. One common issue faced by cooling tower owners is the development of rust in the basins. Rusty basins not only affect the tower’s efficiency but can also lead to severe damage to units and mechanical equipment.

Impact of Rusty Basins

Rusty basins in indoor cooling towers are more than just a cosmetic issue. Over time, corrosion weakens the structural integrity of the basin, making it susceptible to leaks and cracks. When the tower is operational, these leaks can result in water wastage and decreased cooling efficiency. However, the problems don’t end there. Rust particles and debris can circulate within the cooling system, causing damage to pumps, pipes and other mechanical components. This can lead to costly repairs and operational downtime and negatively impacting residential and commercial units during the hotter months.

Importance of Coating Rusty Basins

Coating the rusty basins of indoor cooling towers during the winter shutdown is a proactive approach to prevent further corrosion and protect your investment.

- Prevent Structural Damage: Applying a high-quality coating inhibits rust formation, preventing further structural damage to the basin. It acts as a barrier, shielding the metal surface from moisture and corrosive elements.

- Extend Equipment Lifespan: By addressing rust issues promptly, you prolong the lifespan of your cooling tower and associated mechanical equipment. Regular preventative maintenance and protective coatings can significantly extend the life of the entire system, saving money in the long run and potentially giving you another 10-15 years of service.

- Maintain Efficiency: A rust-free basin ensures optimal water flow within the cooling tower, maintaining its efficiency. When the tower operates smoothly, it consumes less energy and performs at its best capacity. This will save you money with operational costs.

- Prevent Contamination: Rust particles and debris can contaminate the cooling water, leading to fouling and bacterial growth (Legionella). Coating the basin prevents these contaminants from entering the system, ensuring the water remains clean and safe.

- Avoid Cross-Contamination: In facilities with multiple cooling units, rusty basins can contaminate the cooling water supply, leading to cross-contamination between different units. Coating the basins prevents this issue, maintaining the integrity of each system.

Selecting the appropriate coating is crucial to ensuring long-lasting protection for your cooling tower basin. Epoxy-based coatings are commonly used for their excellent adhesion and resistance to corrosion. They offer high durability and chemical resistance, making them suitable for harsh industrial environments.

Addressing rusty basins in indoor cooling towers is not just about aesthetics; it’s a critical maintenance step that safeguards your investment and prevents damage to units and mechanical equipment. By coating the basins during the winter shutdown, you ensure the longevity, efficiency and reliability of your cooling tower system. Regular preventative maintenance, coupled with protective coatings, is the key to a trouble-free and efficient cooling operation, ultimately saving you time, money and headaches in the long term.

Kevin Cherewaty is President of HCTS which repairs, restores and maintains cooling towers. They offer a high-quality coating that inhibits rust formation and prevents further structural damage to the cooling tower basin.

Kevin Cherewaty is President of HCTS which repairs, restores and maintains cooling towers. They offer a high-quality coating that inhibits rust formation and prevents further structural damage to the cooling tower basin.

Find Vendors in these Related Categories

- Building Sciences

- Cleaning & Janitorial Services

- Cleaning Services - Ducts

- Cleaning Services - Windows

- Contractors - Electrical

- Contractors - General

- Contractors - Mechanical

- Door & Lock Services

- Engineering Services

- HVAC

- Maintenance Services - General

- Odour Control

- Painting

- Parking Management/Cleaning Services

- Paving, Concrete and Epoxy Coatings

- Pest Control

- Plumbing Services

- Pressure Washing

- Restoration Services

- Roofing

- Roofing - Green

- Snow Removal Services

- Superintendent Services

- Waste Services

- Water Proofing & Systems

- Window Replacement/Repair